PT. MUROTECH INDONESIA

Our Product

PLATE,HOUSING

U-CAP SEALING

ROTOR, SPEED SENSOR

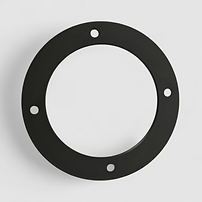

RING 4TH WASHER RETAINING

PLATE OIL GUIDE

SEAT, REVERSE PISTON RETURN SPRING

LOCATING COMP REV SHIFT

LOCK PLATE DIFFERENTIAL BEARING ADJUSTER

PIECE BALANCE

STOPPER CAB RR MOUNTING REBOUND

RETAINER, COTTER

WASHER

PLATE, IDLER PULLEY COVER

WASHER DIFF SIDE GEAR THRUST

SPROCKET

ANGLE SENSOR PLATE

ADJUST NUT

YOKE

PLUG TIGHT

PLATE,CRANK ANGLE-SENSOR

SHIM

SPACER

COVER TRANSMISSION VALVE BODY

SHEET PRIMARY SHEAVE CYLINDER

PLATE, BEARING LOCK

STOPPER CAM SHAFT

CLAMP, SWITCH HARNESS

RETAINER MAIN BEARING

SHEET, PRIMARY SHEAVE CYLINDER

LOCK WASHER

SPACER SPRING PIN

SUB GEAR NO.1

ROD CONNECTING LEVER,PARKING BRAKE

RETAINER,BEARING

VVT PLATE

AND 400+ MORE

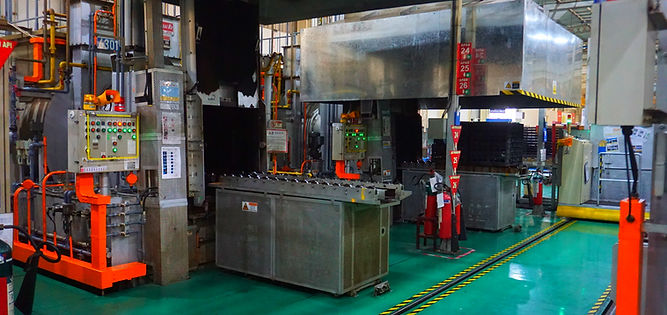

EQUIPMENT

Auto Press Machine 150 ton

(2 Unit)

The function of an auto press machine is to form and cut metal plates automatically, quickly, precisely, and in bulk.

Single Press Machine 150 ton

(1 Unit)

The function of a single press is to press the metal plate once per cycle to cut, drill, or form simple shapes.

Tandem Press Machine 1 Line Set 150 ton (3 Unit), 200 ton (3 Unit)

Tandem press machines function to form metal in stages and automatically, suitable for fast and precise mass production.

Lathe Machine Auto, Semi Auto, Manual (4 Unit)

The function of a lathe machine is to cut, shape, or smoothing metal using cutting tools.

Heat Treatment Furnace

Hot & Cold (2 Unit)

The Heat treatment furnaces function is to heat (above 700°C) and colding metal (under 700°C) in a controlled manner to change its mechanical properties, such as hardness, strength, and toughness.

Tempering Machine

(2 Unit)

Tempering machine functions to reduce brittleness and increase the toughness of metal after the hardening process, by heating the metal to a certain temperature and then cooling it.

Vacuum Washing Machine

(1 Unit)

Vacuum washing machines function to clean metal components from oil, grease, or dirt particles using a vacuum and special solvents, so that the results are clean, dry, and free from contamination.

Surface Grinding Machine

(5 Unit)

Surface grinding machine functions to smooth and level metal surfaces with high precision using a grinding stone.

Grinder Cylindrical Machine (2 Unit)

Grinder Cylindrical machine functions to smooth and shape the inner diameter (hole) of the metal with high precision, using a grinding stone.

Barrel (Vibration, Roll Flow, Centrifugal, Rotary) (8 Unit)

A barrel is a finishing tool used to process the surface of metal components after primary processing using Barrel stone Its purpose is to clean, smooth, polish, and remove burrs or rust from the metal surface.

Burrytack Machine

(3 Unit)

A Burrytack machine removes burrs or sharp edges left over after cutting, pressing, or machining metal components. This prevents defective of product during handling and prepares the part for subsequent assembly or finishing.

Cleanvy Machine

(1 Unit)

Cleanvy machine functions to clean dirt, oil, dust and other contaminants from all metal parts using Ultrasonic technology.

MEASURING EQUIPMENT

For General Inspection

CMM Bridge, Formtracer

(2 Unit)

CMM unit (Coordinate Measuring Machine) is a precision device used in manufacturing to measure the dimensions, shapes, and positions of physical parts in 3D space using X, Y, and Z coordinates. It ensures components meet design specifications by checking distances, angles, and tolerances, typically using units like microns.

Contracer

(1 Unit)

Contracer is a precision measuring device that traces and records the contour (shape) of parts using a stylus. It provides accurate data on curves, angles, and finishes.

Surface Roughness

(1 Unit)

Surface roughness measuring device is used to evaluate the texture or smoothness of a material’s surface by measuring the tiny irregularities (peaks and valleys) present. It typically uses a stylus that moves across the surface to detect variations in height, which are then converted into roughness values like Ra, Rz and Rq. This measurement is crucial in quality control to ensure parts meet functional and aesthetic requirements.

Contamination Unit

(1 Set)

Contamination set is a device that used to detect, measure, and analyze unwanted particles or impurities on or within products and materials. Its function is to ensure that contaminants—such as dust, oils, debris, or microorganisms—are identified and kept within acceptable limits to maintain product quality, safety, and performance. This helps prevent defects, failures, and health risks in manufacturing and final products.

For Heat Treatment Inspection

Rockwell Hardness

(2 Unit)

Rockwell Hardness Device is to measures the hardness of materials by pressing a specific indenter into the surface under a set load and then measuring the depth of the indentation. This test provides a quick and reliable way to assess a material’s resistance to deformation, which is important for determining its strength, durability, and suitability for various applications. The results help ensure that materials meet required hardness specifications for quality and performance.

Vickers Hardness

(1 Unit)

Vickers Hardness device is to measures the hardness of materials by pressing a diamond-shaped indenter into the surface under a precise load and then calculating hardness based on the size of the indentation. This method provides accurate and detailed hardness values, especially for very small or thin samples, making it useful for testing metals, coatings, and thin materials to ensure they meet quality and durability standards.

Micro Vickers Hardness

(1 Unit)

Micro Vickers Hardness device is to measures the hardness of very small or thin materials by using a diamond-shaped indenter with a very light load to create tiny indentations. It provides precise hardness values for fine or delicate samples, such as thin coatings, small parts, or surface layers, helping ensure materials meet strict quality and performance standards without causing damage.